What Motor Powers Remote Control Cars: A Comprehensive Guide

Are you curious about the technology that powers those fast and agile remote control cars? Look no further! In this comprehensive guide, we will delve into the world of remote control car motors and discover the different types of motors used to make these little machines zoom around. From small, budget-friendly options to high-performance motors designed for competition, we will explore the features and capabilities that set these motors apart. So, whether you’re a hobbyist or a seasoned pro, buckle up and get ready to rev your engines!

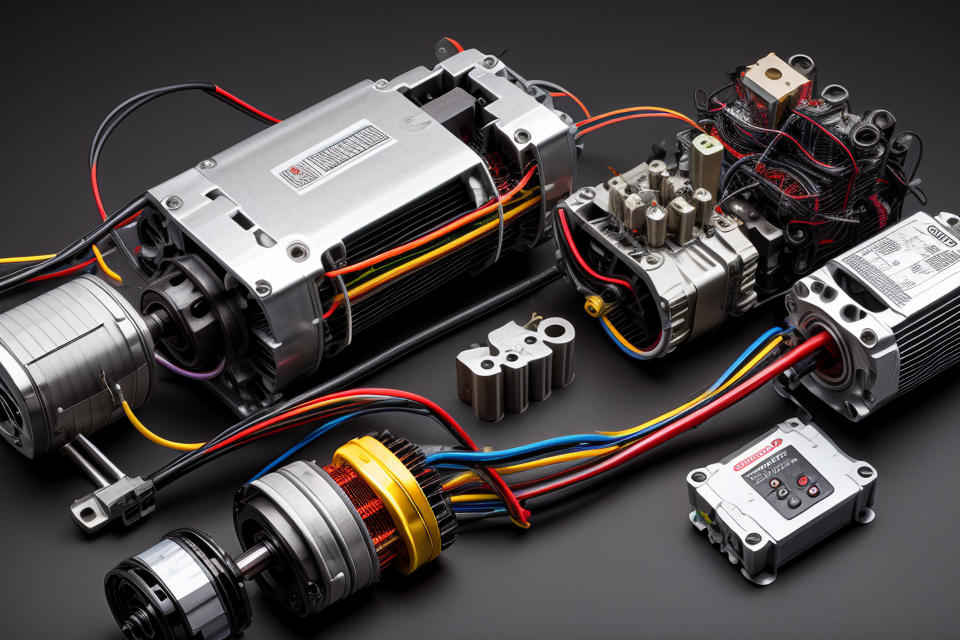

Types of Motors Used in Remote Control Cars

Brushed Motors

DC Brushed Motors

DC brushed motors are one of the most common types of motors used in remote control cars. They consist of a stator, rotor, and commutator. The stator is the stationary part of the motor, while the rotor is the spinning part. The commutator is responsible for switching the direction of the current flow through the motor.

Advantages

DC brushed motors have several advantages that make them a popular choice for remote control cars. They are relatively simple in design, which makes them easy to manufacture and repair. They also have a high power-to-weight ratio, which means they can provide a lot of power for their size. Additionally, DC brushed motors are relatively inexpensive, which makes them a cost-effective option for hobbyists and enthusiasts.

Disadvantages

Despite their advantages, DC brushed motors also have some disadvantages. One of the main drawbacks is that they are not very efficient. They can generate a lot of heat during operation, which can reduce their lifespan and performance over time. Additionally, DC brushed motors require a controller to regulate their speed and direction, which can add complexity to the overall system.

Permanent Magnet Brushed Motors

Permanent magnet brushed motors are similar to DC brushed motors, but they use permanent magnets in the rotor instead of a wound coil. This design makes them more efficient than DC brushed motors, as they do not require a separate winding to create the magnetic field.

Permanent magnet brushed motors have several advantages over DC brushed motors. They are more efficient, as they do not require a separate winding to create the magnetic field. They also have a higher power-to-weight ratio, which means they can provide more power for their size. Additionally, they are simpler in design, which can make them easier to manufacture and repair.

Despite their advantages, permanent magnet brushed motors also have some disadvantages. They can be more expensive than DC brushed motors, as they require more rare earth materials in the rotor. They can also be more difficult to control, as the permanent magnets can cause the motor to rotate in the opposite direction of the controller’s input. Additionally, they may not be as durable as DC brushed motors, as the permanent magnets can be damaged if the motor is subjected to high torque or extreme temperatures.

Brushless Motors

Brushless motors are widely used in remote control cars due to their efficiency, reliability, and high power-to-weight ratio. There are two main types of brushless motors used in remote control cars: Permanent Magnet Brushless Motors and Electronic Speed Control Brushless Motors.

Permanent Magnet Brushless Motors

Permanent magnet brushless motors use a permanent magnet as the rotor and a stator with coils as the rotating magnetic field. These motors are commonly used in RC cars due to their high efficiency and low maintenance requirements.

- High efficiency: Permanent magnet brushless motors have a high power-to-weight ratio, which means they can provide a lot of power while keeping the weight of the car low.

- Low maintenance: Permanent magnet brushless motors have no moving parts, which means they require little maintenance and have a longer lifespan than other types of motors.

-

High torque: Permanent magnet brushless motors can provide a lot of torque, which is important for RC cars that need to climb steep inclines or push through obstacles.

-

Expensive: Permanent magnet brushless motors can be expensive, especially when compared to other types of motors.

- Complex control: Permanent magnet brushless motors require sophisticated electronic speed controllers to control the motor’s speed and direction.

- Limited power: Permanent magnet brushless motors have a limited power output, which means they may not be suitable for high-performance RC cars.

Electronic Speed Control Brushless Motors

Electronic speed control brushless motors use a stator with coils as the rotating magnetic field and a rotor with a permanent magnet as the rotor. These motors are commonly used in RC cars due to their high efficiency and ease of control.

- High efficiency: Electronic speed control brushless motors have a high power-to-weight ratio, which means they can provide a lot of power while keeping the weight of the car low.

- Easy to control: Electronic speed control brushless motors are easy to control using electronic speed controllers, which can be programmed to provide precise speed and direction control.

-

High torque: Electronic speed control brushless motors can provide a lot of torque, which is important for RC cars that need to climb steep inclines or push through obstacles.

-

Expensive: Electronic speed control brushless motors can be expensive, especially when compared to other types of motors.

- Complex control: Electronic speed control brushless motors require sophisticated electronic speed controllers to control the motor’s speed and direction.

- Limited power: Electronic speed control brushless motors have a limited power output, which means they may not be suitable for high-performance RC cars.

Factors to Consider When Choosing a Motor for Remote Control Cars

Power and Torque

Understanding Power and Torque Requirements

When selecting a motor for a remote control car, it is crucial to understand the power and torque requirements of the vehicle. Power refers to the rate at which work is done, while torque refers to the rotational force that produces power. In a remote control car, power and torque are essential to ensure the car can perform at its best.

The power and torque requirements of a remote control car depend on various factors, including the weight of the car, the type of terrain it will be driven on, and the speed at which it needs to operate. For example, a remote control car that needs to climb steep hills or traverse rough terrain will require a motor with higher torque to generate the necessary force to move the car forward.

In addition, the weight of the car plays a significant role in determining the power and torque requirements. A heavier car will require a more powerful motor to generate sufficient torque to move the car forward. Similarly, a remote control car that needs to reach high speeds will require a motor with higher power and torque to achieve those speeds.

Factors Affecting Power and Torque

Several factors can affect the power and torque requirements of a remote control car, including the size and type of the motor, the voltage of the battery, and the gear ratio.

The size and type of the motor are crucial factors to consider when determining the power and torque requirements. A larger motor will generally produce more power and torque than a smaller motor. Additionally, different types of motors, such as brushed or brushless motors, can produce varying levels of power and torque.

The voltage of the battery is another essential factor to consider. A higher voltage battery will provide more power to the motor, resulting in higher levels of power and torque. However, it is important to note that a higher voltage battery may also require a more advanced motor to handle the increased power output.

Finally, the gear ratio is another factor that can affect the power and torque requirements of a remote control car. The gear ratio refers to the relationship between the input and output shafts of the motor. A higher gear ratio will result in slower speeds but higher torque, while a lower gear ratio will result in faster speeds but lower torque. Choosing the right gear ratio is essential to ensure that the motor can generate the necessary power and torque for the specific application of the remote control car.

Weight and Size

When choosing a motor for remote control cars, weight and size are important factors to consider. These factors will determine the speed, acceleration, and overall performance of the car. Here are some considerations to keep in mind when choosing a motor for your remote control car:

Weight and Size Considerations

The weight and size of the motor will directly affect the weight and size of the remote control car. If the motor is too heavy or too large, it can cause the car to be slow and difficult to maneuver. On the other hand, if the motor is too light or too small, the car may not have enough power to handle rough terrain or steep inclines.

Factors Affecting Weight and Size

The weight and size of the motor are affected by several factors, including the type of car, the driving conditions, and the intended use of the car. For example, a car designed for off-road racing will require a heavier and larger motor than a car designed for indoor racing. Similarly, a car designed for slow and controlled driving will require a lighter and smaller motor than a car designed for high-speed racing.

It is important to consider the weight and size of the motor in relation to the weight and size of the car. A motor that is too heavy or too large for the car can cause it to be unbalanced and difficult to control. On the other hand, a motor that is too light or too small for the car can cause it to be underpowered and unable to handle the driving conditions.

When choosing a motor for your remote control car, it is important to consider the weight and size of the motor in relation to the weight and size of the car. By selecting a motor that is appropriately sized and weighted, you can ensure that your remote control car will perform optimally and handle a variety of driving conditions.

Durability and Longevity

Durability and Longevity Factors

When choosing a motor for remote control cars, durability and longevity are crucial factors to consider. A motor that can withstand the rigors of off-road driving and last for an extended period is essential for an enjoyable and satisfying remote control car experience. Some of the key factors that contribute to the durability and longevity of a motor include:

- Material: The material used to construct the motor can impact its durability. Motors made from high-quality materials such as aluminum or titanium are generally more durable than those made from cheaper materials like plastic.

- Build quality: The build quality of the motor also plays a significant role in its durability. A motor with a solid build quality, such as one with a cast aluminum housing, is more likely to withstand the rough handling that comes with off-road driving.

- Bearings: The bearings used in the motor can also impact its durability. High-quality bearings made from materials like steel or ceramic are more durable and longer-lasting than cheaper bearings made from materials like rubber.

Factors Affecting Durability and Longevity

Several factors can affect the durability and longevity of a motor for remote control cars. These include:

- Operating conditions: The operating conditions of the motor, such as temperature and humidity, can impact its durability. A motor that is exposed to extreme temperatures or humidity levels may be more prone to damage or wear.

- Maintenance: Regular maintenance of the motor, such as cleaning and lubrication, can help to prolong its lifespan. A well-maintained motor is less likely to experience wear or damage.

- Driving style: The driving style of the person controlling the remote control car can also impact the durability and longevity of the motor. Aggressive driving, such as high-speed turns or jumps, can put more stress on the motor and increase the risk of damage.

Overall, considering the durability and longevity of a motor when choosing one for remote control cars is crucial for ensuring a long-lasting and enjoyable experience. By choosing a motor made from high-quality materials, with a solid build quality, and high-quality bearings, you can help ensure that your remote control car motor will withstand the rigors of off-road driving and last for an extended period.

Ease of Maintenance

When selecting a motor for remote control cars, ease of maintenance is an important factor to consider. Here are some key factors to keep in mind:

Ease of Maintenance Factors

- Durability

- Accessibility

- Replacement parts availability

Factors Affecting Ease of Maintenance

- Type of motor (brushed or brushless)

- Quality of materials used

- Manufacturer’s reputation for reliability and customer support

- Design features that promote easy maintenance (e.g. screw-on/off connections, modular design)

In summary, when evaluating the ease of maintenance for a motor, it is important to consider the durability, accessibility, and availability of replacement parts. Additionally, the type of motor, quality of materials, and design features can all impact the overall ease of maintenance.

Comparison of Popular Motor Types for Remote Control Cars

Brushed vs. Brushless Motors

When it comes to remote control cars, there are two main types of motors that are commonly used: brushed and brushless motors. Both have their own unique characteristics and advantages, making them suitable for different types of remote control cars and driving conditions. In this section, we will compare brushed and brushless motors in terms of power, efficiency, cost, and durability.

Comparison of Power and Efficiency

Brushed motors have been around for a long time and are still widely used in remote control cars today. They consist of a rotor with permanent magnets and a stator with copper wire windings. The stator creates a magnetic field that interacts with the magnetic field of the rotor, causing it to rotate. Brushed motors are known for their simplicity, low cost, and high power-to-weight ratio, making them ideal for small remote control cars that require a lot of power in a small package. However, brushed motors are less efficient than brushless motors, as they generate heat and energy losses due to the mechanical friction of the brushes.

Brushless motors, on the other hand, use a rotor with permanent magnets and a stator with a sensor that detects the rotor’s position and controls the flow of electricity to the windings. This allows for more precise control of the motor and eliminates the need for brushes, resulting in higher efficiency and less heat generation. Brushless motors are also more powerful than brushed motors, making them ideal for larger remote control cars that require more torque and speed.

Comparison of Cost and Durability

In terms of cost, brushed motors are generally less expensive than brushless motors. However, brushed motors require more maintenance as the brushes need to be replaced regularly, which can add up over time. Brushless motors, on the other hand, have no moving parts to wear out, making them more durable and longer-lasting. While the initial cost of a brushless motor may be higher, it can save money in the long run by reducing maintenance and replacement costs.

When it comes to performance, brushless motors are the clear winner. They offer higher power and efficiency, resulting in faster speeds and longer run times. Brushed motors can still provide plenty of power for small remote control cars, but for larger cars that require more torque and speed, brushless motors are the better choice.

Overall, the choice between brushed and brushless motors depends on the specific needs of the remote control car. Brushed motors are a good choice for small cars that require a lot of power in a small package, while brushless motors are ideal for larger cars that require more torque and speed. Ultimately, it is important to consider the specific requirements of the remote control car and choose a motor that meets those needs.

Permanent Magnet vs. Electronic Speed Control Brushless Motors

Comparison of Performance and Ease of Use

Permanent magnet motors and electronic speed control brushless motors are two popular options for powering remote control cars. Each type of motor has its own set of performance characteristics and ease of use.

- Permanent magnet motors are known for their simplicity and reliability. They are easy to use and require minimal maintenance. These motors are also known for their consistent performance, which makes them a popular choice for remote control car enthusiasts.

- Electronic speed control brushless motors, on the other hand, offer more advanced features and performance capabilities. They allow for greater control over speed and torque, and can be programmed to suit specific driving conditions. While these motors may require more maintenance and have a steeper learning curve, they offer a higher level of performance for experienced remote control car drivers.

When it comes to cost and durability, both types of motors have their own advantages.

- Permanent magnet motors are generally more affordable and can withstand rough handling. They are a popular choice for entry-level remote control cars and for hobbyists on a budget.

- Electronic speed control brushless motors are typically more expensive but offer better durability and performance. They are a popular choice for experienced remote control car drivers who demand high-performance capabilities and are willing to invest in the best equipment.

Overall, the choice between a permanent magnet motor and an electronic speed control brushless motor will depend on the specific needs and preferences of the remote control car enthusiast. Both types of motors have their own advantages and disadvantages, and the best choice will depend on the specific application and driving conditions.

Selecting the Right Motor for Your Remote Control Car

Factors to Consider

When selecting the right motor for your remote control car, there are several factors to consider. These include the type of car, the intended use, the weight and size of the car, and the performance requirements. Additionally, the battery type and voltage should also be taken into account as they can affect the motor’s power output and durability.

Recommended Motor Types for Different Types of Remote Control Cars

Different types of remote control cars require different motor types to meet their specific needs. Here are some recommended motor types for different types of remote control cars:

- Off-road cars: Brushed motors with high torque and a low gear ratio are recommended for off-road cars. These motors provide the power needed to climb steep inclines and navigate through rough terrain.

- On-road cars: Brushless motors with high RPM and low current draw are recommended for on-road cars. These motors provide the speed and precision needed for racing on smooth surfaces.

- Rock crawlers: Brushed or brushless motors with low RPM and high torque are recommended for rock crawlers. These motors provide the power needed to climb over rocks and navigate through tight spaces.

- Monster trucks: Brushed or brushless motors with high torque and a low gear ratio are recommended for monster trucks. These motors provide the power needed to jump and crash through obstacles.

In summary, selecting the right motor for your remote control car depends on several factors, including the type of car, the intended use, and the performance requirements. Recommended motor types for different types of remote control cars include brushed or brushless motors with high torque and low RPM for off-road cars, high RPM and low current draw for on-road cars, low RPM and high torque for rock crawlers, and high torque and low gear ratio for monster trucks.

Final Thoughts on Choosing the Right Motor for Your Remote Control Car

When it comes to choosing the right motor for your remote control car, there are several factors to consider. First and foremost, you’ll want to think about the type of terrain you’ll be driving on. If you plan on racing your car on smooth, flat surfaces, then a brushless motor may be the best option. However, if you expect to encounter rough terrain or obstacles, then a brushed motor may be more suitable.

Another important factor to consider is the power output of the motor. Higher power output typically means faster speeds and better performance, but it can also lead to shorter motor lifespan. On the other hand, a lower power output may result in longer motor life, but may not provide the same level of performance.

In addition to these factors, you’ll also want to consider the size and weight of the car, as well as the type of battery you’ll be using. All of these factors can impact the overall performance of your remote control car, and can help you make an informed decision when choosing the right motor for your needs.

Ultimately, the right motor for your remote control car will depend on your specific needs and preferences. By considering the factors mentioned above, you can ensure that you choose a motor that will provide the best possible performance and longevity for your vehicle.

FAQs

1. What kind of motor is used in remote control cars?

The most common type of motor used in remote control cars is a brushed electric motor. These motors are powered by a 12-volt battery and are designed to provide high torque and speed.

2. What are the advantages of using a brushed electric motor in remote control cars?

One of the main advantages of using a brushed electric motor is that they are relatively cheap and easy to install. They also provide a good balance of power and weight, making them ideal for remote control cars. Additionally, they are very responsive to changes in direction, which makes them ideal for racing and other competitive events.

3. Are there any disadvantages to using a brushed electric motor in remote control cars?

One of the main disadvantages of using a brushed electric motor is that they can wear out quickly if not properly maintained. Additionally, they can be relatively noisy, which may not be ideal for all users. Finally, they are not as efficient as some other types of motors, which can lead to a shorter battery life.

4. Are there any other types of motors used in remote control cars?

Yes, there are several other types of motors that can be used in remote control cars, including brushless DC motors and combustion engines. Brushless DC motors are more efficient than brushed motors and can provide more torque and speed. Combustion engines, on the other hand, are typically used in larger remote control cars and can provide a lot of power, but they can also be more difficult to maintain and control.

5. How do I choose the right motor for my remote control car?

When choosing a motor for your remote control car, you should consider factors such as the size and weight of the car, the type of terrain you will be driving on, and your personal preferences for speed and power. You should also consider the type of motor you are comfortable working with and maintaining. It is always a good idea to consult with other hobbyists or experts in the field to get recommendations and advice.